Fars Rizan Mavad Company, with the support of 50 years of experience, Fars Iran Company, as the first producer of casting industry additives in Iran, started its activity in 1354, and with the executive and technical management of expert experts and in accordance with the world’s technology, it is currently the largest producer. The types of additives used in casting industries in Iran.

Using the best raw materials

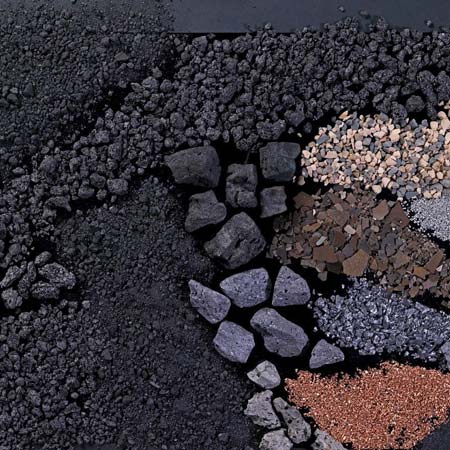

We use the best raw materials to make casting additives

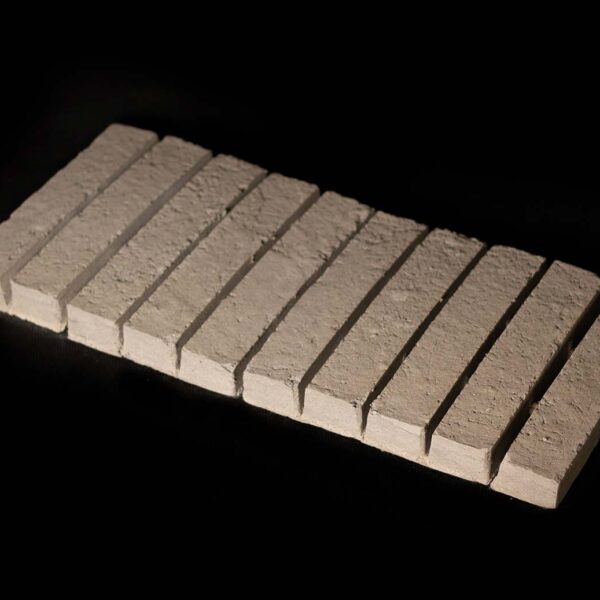

One of the main requirements of casting units is the types of sand. Casting sand can be used as casting molds for metals such as steel, black iron, aluminum, copper, etc., or it can be used as refractory in making ceramic, glass, and cement furnaces.

There are different types of casting sand, among which we can mention silica sand, chamotte sand, chromite sand, zirconia, olivine and iron silicate. Silica sand is used for most sand castings. Fars Rizan Materials Company uses the best raw materials to make its products.

- The best type of sand

- The best type of iron silicate

- Using the most up-to-date equipment

- The standards of the day of the world

Fill out the form below and our experts will contact you as soon as possible

Plugin "Contact Form 7" not installed or activated

Call for information on product availability and the latest price

More than 50 years of experience

More than 40 years of experience in the production of casting industry additives in Iran

Fars Rizan Mavad Company, with the support of 40 years of experience, Fars Iran Company, as the first producer of additives in the casting industry in Iran, started its activity in 1354 and with the executive and technical management of expert experts and in accordance with the world’s modern technology, it is currently the largest producer. It is the main and reliable supplier of all kinds of casting industry additives and large casting industries of the country.

- 50 years of production experience

- Modern technology

- Specialist experts

- The largest manufacturer of casting additives